Keys to the successful design and construction of an accessible bathroom:

Figure 11 - Rounded corners in shower enclosure

Molded bathtubs and showers that have rounded corners, as shown in Figure 11, and slope towards the drain assuring that all latent water is drained from the fixture will help to prevent the growth of mold and mildew.

Textured finishes on wall and floor tiles are harder to clean than smooth surfaces. Grout between tiles should have a penetrating sealer applied which will also help to prevent the growth of molds and mildew.

Do not assume that any product can be cleaned using any cleaner. Read the manufacturer’s cleaning instructions before purchase.

Cleaning supplies should be stored conveniently and yet out of reach of children and individuals with any mental disability. If necessary consider a locked cabinet.

Safety considerations:

The bathroom is where many accidents in the home occur. Most bathroom accidents can be attributed to wet and slippery surfaces, including floors, bathtubs and showers.

Non slip flooring is a crucial consideration for bathroom floors.

Bathmats on the bathroom floor are considered, by most safety experts, to be more of a hazard than a safety device. While they may reduce slipping on wet floors, they become a trip hazard and can be a major hurdle for young children, anyone using a walker or someone who is not 100% stable when they walk.

Figure 12 - Thermostatic mixing valve

Non-slip mats used in bathtubs do provide a good level of safety prevention.

Being scalded is a common safety issue in the bathroom. Mixing valves with water temperature limiting can be preset to prevent scalding. Temperature controlled mixing valves should be set to a maximum temperature of 120 degrees F. or 49 degrees C.

Another item that should be considered is sharp edges. This is common on vanity tops that do not butt up against walls. Countertop edges should be rounded so that if an individual does fall there is less chance of harm, occurring.

Grab bars

The installation of grab bars either immediately or in the future should be considered in the early stages of bathroom construction or renovation.

Grab bars only have value if they are fastened to walls securely. Most standards require that grab bars be able support at least 290 lbs (133kg) of weight. Fastening a grab-bar to a drywall without structural support behind that grab bar has little value.

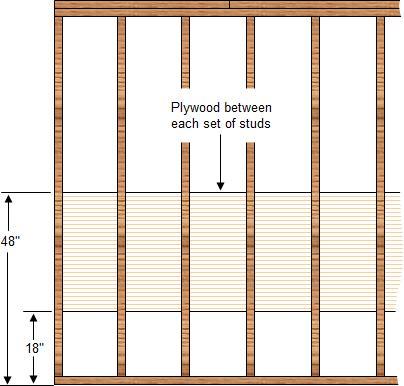

Trying to hit wall studs in order to fasten grab bars securely to walls can be a difficult exercise, as you can be reasonably confident that the studs will not be located in the positions that you require. To avoid this problem consider placing a sheet of 1/2 inch (16 mm) plywood between the stud walls, all around the perimeter of the room at a height of 18 inches, (450 mm) to 48 inches, (1200 mm), as shown in Figure 13.

Figure 13 - Adding plywood on bathroom stud walls to support grab bars

Adding the plywood to the walls has a secondary benefit; it will make it easier to install towel bars and vanities against walls.

Although towel bars cannot act as grab bars, grab bars can act as towel bars.

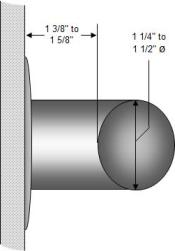

There are a many styles and sizes of grab bars. It is recommended that the best choices for grab bars are those that have a diameter of 1 1/4 inches to 1 1/2 inches (30 to 40 mm). With a distance of between 1 3/8 inches (35 mm) and 1 5/8 inches (45 mm) from the wall, as shown in Figure 14.

Figure 14 - Grab bar sizing

A minimum of 6 inches (150 mm) should be provided as unobstructed clearance above the bar.