Before You Start:

Always call all the local utilities before you dig your footings. They will come out, free of charge, and mark the location of any underground power cables, telephone lines, cable TV and gas pipes on your property. If you cut a line or pipe and did not call, you are responsible for having the damage repaired, if they came out and missed a location and you damage a line or pipe, they are responsible.

Materials:

The lumber or material that you choose will depend on your budget and the desired appearance of the finished deck flooring.

The most common lumber used for decks is pressure treated. Pressure treated lumber has a decay life in excess of 40 years. However pressure treated lumber is green in color and does not take stain, if you want your deck finished it must be painted.

In some areas, especially California, it is common to use redwood and in some of the Northern states cedar is common. Both of these lumbers have a resistance to decay from moisture.

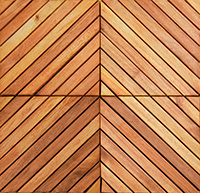

A new entry into deck flooring are interlocking deck tiles made from wood as well as composite materials as shown in Figures 3, 4 and 5. Using deck tiles requires a sub-floor. This makes them an ideal choice for homeowners who want to create a new deck flooring appearance without the complexity associated with the tear-down and construction.

Typical Interlocking Deck Tiles

Figure 3 - 4 strip deck tile

Figure 4 - 6 strip deck tile

Figure 5 - 12 strip deck tile

As well as interlocking deck tiles there are numerous composite (Figure 6) and other non wood (Figure 7) plank materials:

Figure 6 - Composite decking material

Figure 7 - Vinyl decking material

Composite materials are becoming more and more common for the deck flooring and railings. Numerous manufacturers are creating a wide selection of shapes, colors and textures.

Selection of deck tiles.

Items to Consider:

- Do not butt the flooring boards against each other, allow between 1/8 and 3/16 of an inch of air space. This will allow for water to drain off the flooring boards. It also allows for expansion in high heat.

- It is wise to seal cedar and redwood with a penetrating sealer.

- It is wise to seal the cut ends of pressure treated lumber with a penetrating sealer that is made for pressure treated lumber.

- Always use galvanized or coated deck screws, bolts and nails. If you are using pressure treated lumber stainless steel fasteners are highly recommended.

- If using lag bolts, pre-drill the hole or you will more than likely split the lumber.

- It is not healthy to inhale the saw dust created when cutting pressure treated lumber, composite or vinyl materials. A dust mask should always be worn.

- Lumber that is in contact with the ground or embedded in or in contact with concrete should be special-treated lumber manufactured and approved for ground contact. If you are resting columns or posts on concrete a piece of folded tar paper placed between the lumber and the concrete will help to prevent moisture from being drawn up into the lumber.

Additional Deck Information: