Note: R-Values that are stated throughout the site are averages for the type of insulation product. Manufacturer's specific R-Values may vary for a type of insulation. R-Values marked on packages or quoted by specific manufacturers should be considered as correct.

Overview:

With today's high cost of energy to heat and cool homes it has become imperative to reduce the heat energy consumed by every homeowner.

Insulation is sold based on its R-Value. The R-Value of insulation is the measurement of the insulations ability not to transfer heat. Higher R-Values provide better insulating qualities.

When reviewing insulation it is important to read labels and manufacturers' specifications closely. Some manufacturers and some products specify an R-Value based on an inch of the product's installation. This is very common with loose fill type insulations, because the end R-Value is only relative to how much product you use. Whereas preformed insulation such as foam and batts will quote insulation as a function of the finished product.

Note: When installing insulation it is important to wear adequate safety products, including, glasses or goggles, dust mask or respirator, work gloves and coveralls.

There are 5 primary types of insulation that can be used in the home:

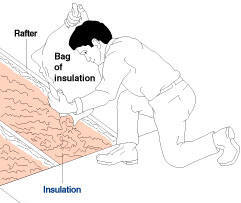

Figure 1 - Loose fill cellulose insulation

- Loose Fill Insulation:

Loose fill insulation (Figure 1), when properly installed, fills all vacancies between walls, and boards. It has the inherent advantage that it will fill even very small areas that are difficult to insulate with other types of rigid or packaged materials.

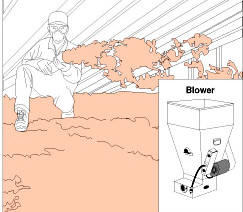

Although some (read the manufacturer's labels and specifications for installation methods) loose fill insulation can be installed by pouring the contents (Figure 2a) into the void a much better finished result will be obtained by the use of a machine to blow (Figure 2b) the insulation into the void or cavity.

Cross members, wires, pipes and duct work, within an attic, create a major installation problem when trying to use anything but a loose fill insulation.

Figure 2a - Installing loose fill insulation by hand

Figure 2b - Installing loose fill insulation with a blower

- Cellulose Fiber Insulation (R-3.7/inch)

- Stabilized cellulose fiber insulation is designed to be used in damp applications. It is installed by adding water to the insulation as it is blown in to the area. This type of insulation requires specially designed blowers.

- Fiberglass Insulation (R-2.3-2.8/inch)

- Mineral Wool (R-3.2/inch)

- Vermiculite (R-2.4/inch)

An excellent choice for the environmentally conscious homeowner. Cellulose fiber insulation is a recycled material made by grinding used paper into fibers and blending it with pesticides and fire retardant chemicals.

Although it can be used in new construction it is generally the insulation of choice in previously built homes that need to have insulation added. Because it can be blown into voids it is the popular insulation for walls and attics.

Note: Different cellulose fiber insulation requires different types of blower machines to properly handle the product. If you are renting a blower, ensure that it is made for the cellulose fiber insulation that you have purchased.

Cellulose fiber also is an excellent choice for walls that have air leak problems as the insulation not only provides an excellent thermal barrier but stops air flow.

The most common of the loose fill insulation products is a fiberglass material.

Often termed slag or rock wool it is made from molten slag, the waste created during the smelting of iron ore. The biggest advantage of mineral wool is that it is 100% fireproof, whereas cellulose fiber is chemically treated to be fire retardant and fiberglass melts when exposed to high temperatures.

A heavy, by weight, insulation, it is uncommon to use it in attics. Its most common application is providing insulation to concrete block foundations by filling the center cores of the blocks with the material. It is one of the best choices of insulation for areas that may be subjected to moisture. It can easily be installed manually without a blower.