This article provide an overview of how to remove a load bearing wall. A professional structural engineer or licensed architect can provide the exact details for your specific situation. We highly recommend consulting a professional before attempting to remove a load bearing wall.

----------------------

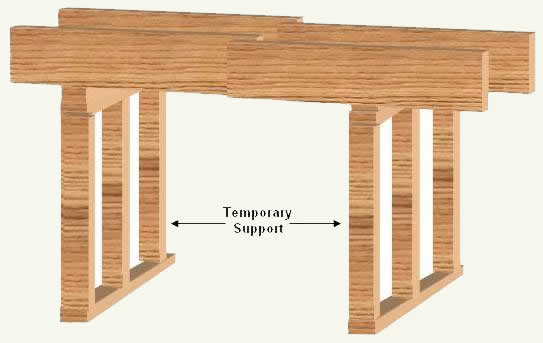

Before you can remove a load bearing wall you must support the load in another manner. Although there are a few methods that can be used, the easiest and most popular is to build a support wall. This drawing indicates that the load being supported is coming from both directions, see Figure 4. If your load is only in one direction you only need to support the load from that direction. A load coming from only side is, of course, the situation on exterior walls, but it can happen on interior walls, such as stairwells.

Construct temporary 2" x 4" stud and plate walls approximately 3' away from the wall you are planning on removing or cutting into. Three feet should provide you with ample space to remove the old wall and install the new supporting structure.

Figure 4 - Temporary supports installed in order to remove a load bearing wall

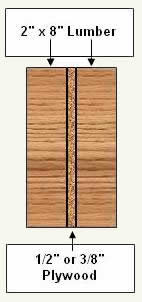

The replacement support structure needs to have a header installed, see Figure 5. The header is made up of 2" material, the width is determined by the width of the opening and the load. This should be checked with your local building department. However, as a rule of thumb, the width in inches generally corresponds to the length in feet. A 6 foot opening would use a header made from 2" x 6" lumber, an 8 foot opening would use 2" x 8" and a 10 foot opening would use 2" x 10" lumber.

Figure 5 - Header design for new load bearing wall opening

The header is made by sandwiching a piece of 3/8" or 1/2" plywood between 2 pieces of lumber. Check the thickness dimension of your 2 inch lumber. It should be 1 5/8" which means that 2 together add up to 3 1/4". Check the width dimension of your 2" x 4" lumber it should 3 5/8". All of this means that a piece of 3/8" thick plywood with 2 pieces of lumber will equal 3 5/8". If however, the dimensions of your lumber is different you may need to use a 1/2" piece of plywood to get to the same width as your 2" x 4" lumber. Use plywood in between the lumber not OSB, chip board or particle board.

Nail the sandwiched lumber together from both sides using 3 1/2" common or ardox nails. I also suggest using some construction adhesive. Use plenty of nails!

The finished support wall should look like like Figure 6.