Problem: Shingle deformation and displacement.

Cause: Improper or inadequate roof deck or improper fastening of shingles.

Many different factors can deform of displace asphalt shingles. Lumber-deck movement, incorrect sheathing thickness, spacing or installation, nail pops in the sheathing, and incorrect shingle fastening can all be factors. Persistent deformation of the decking/sheathing will weaken the roof and provide openings in the shingles through which water can penetrate.

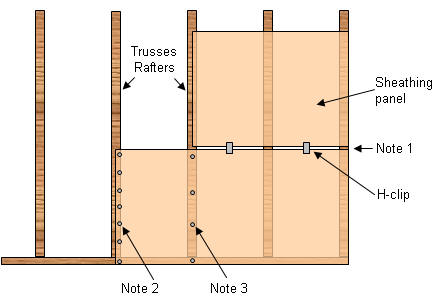

Solutions: Provide a proper base on which to apply the shingles and ensure that the shingles are properly fastened as shown in Figure 4.

Figure 4 - Roof Sheathing Installation

Note 1: Allow a 1/8 inch (3mm) gap.

Note 2: Nail edges of sheathing at 6 inches (150 mm) o.c.

Note 3: Nail center portion of sheathing at 6 inches (150 mm) o.c.

- Avoid lumber-deck movement associated with wet lumber. When asphalt shingles are installed over a green-lumber base, they often buckle as the wood dries and shrinks.

- Use dry lumber or let the lumber dry to 19% moisture content before applying the asphalt shingles. Ventilate attic space to reduce humidity that can cause the decking to swell and expand.

- Reduce the problem of deck movement by using sheathing panels instead of board lumber for the roof deck.

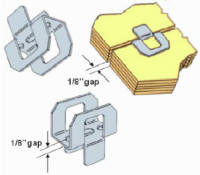

Figure 4a - Roof sheathing H-clips

- High wind loads will make the roof deck vibrate if the deck material is too thin or insufficiently rigid. Such vibration can loosen the shingle fastening. The required thickness of sheathing is a function of the span from rafter to rafter. Most building codes require plywood and 0-2 grade waferboard and strandboard to be a minimum of 5/16 inch (7 mm) thick when supports are spaced 16 inches (400 mm) o.c. and the edges are supported. The thickness required for supports at 24 inches (600 mm) o.c. is 3/8 inch (9 mm).

- If green lumber is used to sheathe the roof, shrinkage of the lumber may cause nails to pop This can damage the waterproof characteristics of the asphalt shingle roof.

Edges can be supported using roof sheathing H-clips, as shown in Figure 4a.

Figure 4b - Shingle nail

- The two most important characteristics of shingle nails are the head size and the nails' resistance to rust. Nails must be long enough to penetrate at least 1/2 inch (12 mm) into the roof sheathing. The head diameter should not be less than 3/8 inch (9 mm) and the shank should be no less than 1/8 inch (3 mm). Staples used with asphalt shingles are not to be less than 3/4 inch (19 mm) long, not less than 1/16 inch (2 mm) in diameter or thickness and have a crown no smaller than 1 inch (25 mm).

- Most building codes require that shingles be fastened with no fewer than four nails or staples for a 40 inches (1 m) wide shingle. The number of fasteners may be reduced for narrower shingles in proportion to the width of the shingles. Place fasteners between 1 inch (25 mm) and 1 1/2 inches (40 mm) from each end, with the other fasteners spaced equally between. Inadequate shingle fastening can result in displaced shingles and openings for water to penetrate. Always refer to roofing manufacturers' installation instructions as shown in Figure 5.

Figure 5 - Proper Asphalt Shingle Installation

Note 1: Minimum 2 inches (50 mm) head-lap.

Note 2: First course of shingles is either a solid strip of rolled shingle material or shingles installed in the reverse direction - slits pointing up.

Additional information on roofs and roofing