Problem: Cold interior surfaces promoting condensation and growth of molds and mildew.

Cause: Thermal bridging across solid elements of the wall assembly.

Thermal bridging occurs when there is a direct path for heat flow from the interior of the building to the exterior. Exterior wall studs and plates encourage the transmission of heat through walls and can promote localized condensation, mildew growth, and dust marking. Less noticeable will be increased conductive heat losses, higher energy bills, and diminished occupant comfort. Thermal bridging will be most noticeable where framing members are concentrated - such as at corners.

Reduce the amount of lumber used in wall framing, or provide a thermal break in the wall system.

Solutions:

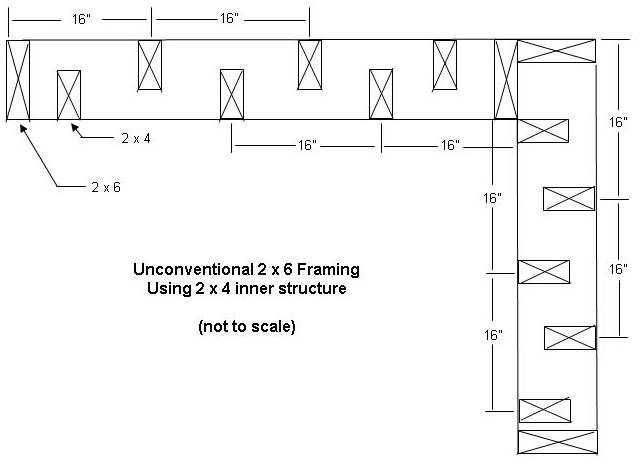

- Use the maximum stud spacing permitted by the building code to reduce the number of studs, which are responsible for thermal bridging as shown in Figure 16. Stud spacing must accommodate building code requirements for fastening and thickness of exterior sheathing and cladding.

Figure 16 - Percentage Of Stud Surface in Wall Section

- 24 studs in 30' (9 m), 10% of section

- 24-16/24 = 30% reduction in thermal bridging

- 16 studs in 30' (9 m), 6.7% of section

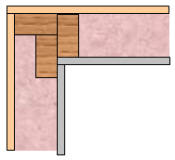

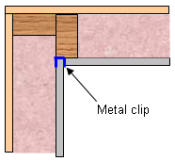

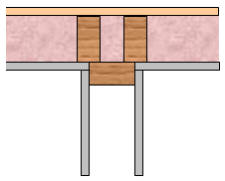

- Reduce the number of framing members used in corner and partition intersection details. Use nailing clips to support drywall of exterior sheet materials as shown in Figures 17a, 17b, 17c, 17d and 17e

Figure 17a - Three wall studs used to support corner intersection

Figure 17b - Two wall studs and metal drywall clips used to support corner intersection

Figure 17c - Three wall studs used to support partition intersection

Figure 17d - One wall stud and 1 x 6 used to support partition intersection

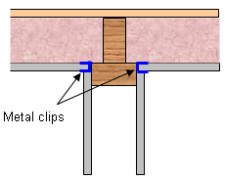

Figure 17e - Two wall studs and metal drywall clips used to support partition intersection

- Use single top-plates where the design allows for floor joists and trusses to be directly located over the stud below as shown in Figure 18.

Figure 18 - Aligned Wall Framing Members

- In load-bearing exterior walls, fabricate structural box beams to serve as headers over doors and windows. The use of structural sheathing on both sides of the framing allows for the incorporation of high levels of insulation at headers as shown in Figure 19. Single lintels notched into side of stud framing can be used where building codes allow.

Figure 19 - Reduced Header Over Window

- Use exterior insulated sheathing to provide a thermal break for the framing. Many builders now install exterior insulated sheathing between the exterior wall frame and the exterior finish to provide an additional thermal break.

- Use a combination of 2 X 6 and 2 X 4 lumber (additional information) to create the stud wall as shown in Figure 19b.