Having the right tools to for the right job is critical if you want the project to be successful and very few tools are more important than your choice of the correct circular saw blade, Figure 1, for cutting the material you are working with.

Figure 1 - Circular saw blade

Circular saw blades are used on a number of different stationary and hand power tools. Circular saw blades are used on portable circular saws, Figure 2; cut-off, chop saws or miter saws, Figure 3; table saws, Figure 4; and radial arm saws, Figure 5.

Figure 2 - Portable circular saw

Figure 3 - Miter saw

Figure 4 - Table saw

Figure 5 - Radial arm saw

Figure 6 - Inexpensive circular saw combination blade

Additional information on:

table saws, chop saws, miter saws and radial arm saws.

When you purchase any of the power saws previously mentioned, it will come with a circular saw blade. In most cases the circular saw blade that is included is an inexpensive combination blade, as shown in Figure 6, designed for ripping and cross cutting rough lumber. If your project involves cutting framing lumber then the combination blade supplied with your new power saw may be acceptable, however its life, in most cases will be limited.

When purchasing a new circular saw blade it is important that you take note of three different dimensions as your circular saw will have some parameters for the size of blade you can use in that specific piece of equipment:

- The diameter of the blade:

- The arbor size:

- The maximum kerf size:

Circular saw blades are available in a range of diameters from as small as 3 3/8″ to 16″. The most popular sizes are 7 1/4″ for hand held circular saws; 10″ for table saws, 10″ and 12″ for radial arm and miter saws.

The arbor size relates to the hole in the center of the circular saw blade. The arbor sizes range from 1/2″ to 1″. Some circular saw blades will have a knock-out in the hole which allows you to use that specific blade for two different sized arbors.

Note: Once the knock-out has been removed you cannot use the circular saw blade on the smaller sized arbor.

The kerf is the width of the saw blade at its widest point. In general the wider the kerf of a saw blade, the better its quality. Wider kerf blades will last longer and can have the teeth sharpened.

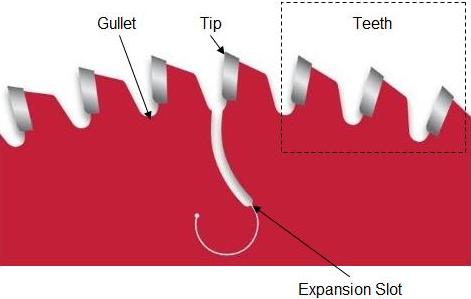

After determining the dimensions of the required circular saw blade you can then look at individual features. Circular saw blades have 4 basic parts that set them apart from other circular saw blades, as shown in Figure 7.

Figure 7 - Circular saw blade components

- Quantity of teeth:

- Depth of Gullet:

- Type of tip:

- Expansion slot:

If you are looking for a very smooth cut, you want more teeth, however there is a trade-off. The more teeth on the circular saw blade the slower the cutting action.

The gullet provides an area for the saw dust to be collected and expelled from the circular saw blade. In general the more teeth on the circular saw blade the shallower the gullet. When ripping lumber you generally want a deep gullet.

The most common inexpensive circular saw blades use a steel tip that has been created out of the basic circular saw blade metal disc. More expensive blades will have carbide tips that have been bonded to the blade, which last longer. There are also circular saw blades with diamond tips and circular saw blades that are abrasive wheels for specialty applications such as cutting masonry, ceramic and natural stone tiles and metal.

As the circular saw blade cuts the material it will heat-up and hence expand due to the friction between the circular saw blade teeth and the material they are cutting. Expansion slots are designed to allow the expansion to be controlled so that the blade does not deform and warp as it is cutting the material.