Problem: Noise Problems - Floor Squeaks 3

Cause:

Underlay movement.

Underlay panels do not move if they have been installed properly on a solid base.

Fasteners that are not fully secured or become loose will allow the underlay panels to move up and down on the shaft of the fastener, resulting in squeaking.

If the fasteners are loose, or if an insufficient number of fasteners is installed, the edges of the underlay panels can run against one another, causing squeaking.

Solutions:

Fasten the underlay adequately.

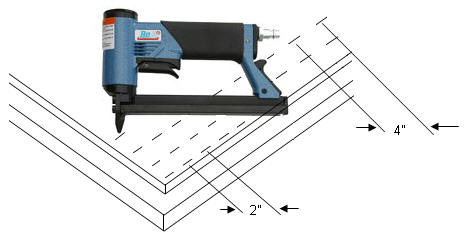

- Fastening the underlay panels is critical to eliminating movement. Most building codes require that staples, annular grooved floor nails or spiral nails be installed not more than 6″ (150 mm) on center along the edges and not more than 8″ (200 mm) on center in both directions at other locations. The underlay manufacturers recommend even closer spacing's between 2″ (50mm) on center and 4″ (100 mm) along edges and between 4″ (100 mm) on center and 6″ (150 mm) on center at other locations as shown in Figure 6.

Figure 6 - Fastening Underlay Panels To The Subfloor

- Some builders use construction adhesive along with staples when installing underlay. The use of construction adhesive is highly recommended.

Install underlay on a strong, stable base.

- Any movement of the underlay can result in squeaking and problems with the finish flooring. If the subfloor is spongy and moves when loaded, the underlay will squeak along panel edges. Follow building code or manufacturer recommendations for base requirements.

- Joints in underlay panels must be offset more than 8″ (200 mm) from joints in subfloor panels.