- Batt & Blanket Insulation:

By far the most common type of insulation batt or blanket insulation is generally made of fiberglass. The fiberglass strands are woven to create a unified body of material. Ninety percent of new homes built in North America are insulated with fiberglass batt or blanket products. Although not as common batts and blankets are also made of rock wool. Batts and blankets are the easiest insulation material to install in gaps between ceiling rafters and wall studs as they are made to the common separation centers found in new construction - 12 and 16 inches.

Batts are normally sold in 4 foot lengths, although 8 foot is also available. This makes the product a standard fit in most new construction walls.

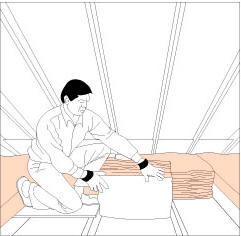

Figure 2a - Installing insulation batts between roof rafters in attic

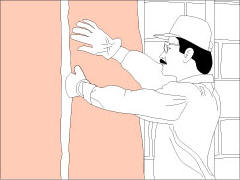

Figure 2b - Installing insulation batts between furring strips on block wall

Blankets are made into rolls and are generally the product of choice for attics where spans are much longer than 8 feet.

Table 1

| |

Thickness In Inches |

R-Value |

3.5 |

R-11 |

3.5 |

R-13 |

3.5 |

R-15 |

6.25 |

R-19 |

5.5 |

R-21 |

8.5 |

R-30 |

12 |

R-38 |

- Batt & Blanket Facing:

- No facing (bare fiberglass on both sides of the batt) (Figure 3),

- Paper facing (Figure 4),

- Foil facing (Figure 5).

Note 1: The R-Value of a batt or blanket of fiberglass insulation is not necessarily relative to its thickness.

Manufacturers have developed methods to pack more fiber into the same thickness and hence have increased the R-Value without increasing the thickness, see Table 1.

With batts and blankets that are 3.5 inches thick you can get 3 different R-Values. As well, it should be noted that a 6.25 inch thick batt or blanket has a lower R-Value than one that is 5.5 inches thick. Do not buy your insulation based on the thickness of the batt or blanket. Purchase it based on the R-Value!

Note 2: Do not force a thicker batt into a thinner location. If you have 2″ × 4″ studs, you must use a 3.5 inch batt. If you try to force a thicker batt into the void you will reduce the R-Value. It is the air pockets trapped between the fibers that provide the insulation. Simplistically, the more air pockets the greater the R-Value. When you force a fiberglass batt to become thinner than it is designed to be, you reduce the number of air pockets and hence, reduce the R-Value.

Safety - When installing insulation it is important to wear adequate safety products, including, glasses, goggles, dust mask, respirator, work gloves and coveralls.

There are 3 types of batts and blankets available:

Figure 3 - Unfaced fiberglass insulation batts

Figure 4 - Paper faced fiberglass insulation batts

Figure 5 - Foil faced batt insulation

The facing does not provide any additional insulation factor. Facings provide some moisture control and they also provide an edge that allows for conveniently stapling the batt or blanket to studs or joists to hold them in position.

Batts and blankets that do not have one face covered with paper of foil are commonly made slightly larger than the common centers on studs and joists to provide a friction fit when placed in position. If you have installed a proper vapor barrier you do not gain anything by using faced batts or blankets.