Nails and screws come in a wide assortment of lengths, thicknesses and head types, (Figure 1). While many home handymen look amongst their vast collection of left over nails and screws in the hope of finding something that "will do", more attention should be paid to selecting the correct fastener for each and every job.

Figure 1 - Assortment of nails and screws

Screw & Nail Considerations:

- What materials are you joining together. There are different fasteners depending on whether you have wood, masonry, drywall, etc.

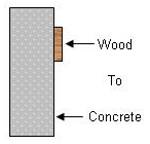

- Use a masonry fastener when you are attaching wood to masonry, as shown in Figure 2

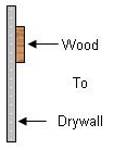

- Use a drywall fastener when you are attaching wood to drywall, as shown in Figure 3.

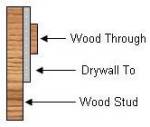

- Use a wood fastener when you are attaching wood to drywall, but are using the wood stud behind the drywall for support, as shown in Figure 4.

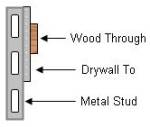

- Use a metal fastener when you are attaching wood to drywall, but are using the metal stud behind the drywall for support, as shown in Figure 5.

When joining dissimilar materials or in cases where there is a secondary layer of material that is being penetrated, the fastener chosen should be based on the material that is doing the holding, not the material being held or the material sandwiched between the other materials.

Examples of Fastener Choices

Figure 2 - Use a Masonry Fastener

Figure 3 - Use a Drywall Fastener

Figure 4 - Use a Wood Fastener

Figure 5 - Use a Metal Fastener

Additional information is available for concrete fasteners and drywall fasteners.

- The thickness of both the material being held and the material doing the holding is key.

- The weight and load will have an effect on the type of fastener chosen. However, it should be noted that the best way to connect heavy loads is to increase the number of fasteners rather than the size of an individual fastener.

- Screws will carry a heavier load than a nail of the same size in length and diameter. Screws will not loosen as easily as nails will if the load is subject to any vibration. Screws allow for easier disassembly of the materials.

- The choice of material that the fastener is made of can be critical to the longevity of the connection. When fastening any metals, be it the holding material or the held material, you must be careful in the choice of fastener material. Many dissimilar metals create galvanic corrosion. If in doubt use stainless steel fasteners. Pressure treated lumber contains large amounts of copper. Steel fasteners will corrode in a matter of months.

| Fastener Length | ||

Wood |

3 X Thickness of material being held |

|

Metal |

1.5 to 2 X thickness of material being held |

Do not use |

Masonry |

1" longer than material being held |

3/4" longer than material being held |

The use of an anchor or fasteners for masonry may be the best fastening method |

||

Drywall |

Use drywall fasteners |

|

Nails:

Nails have been around for hundreds of years, but over the last 50 years the varieties have increased exponentially. Nails are generally sold by their weight and length and in most cases as they get longer they also get thicker.

Quantity Needed:

The following information provides an estimate of the amount of nails that will be needed for a specific project:

- Deck Flooring - 1 lb. of 2 inchscrews for every 100 lineal feet

- Drywall - 1 lb. of 1 1/4 inch screws for every 288 sq. ft. of drywall (9 - 4 X 8 sheets)

- Framing Construction - 1 lb. for every 10 lineal feet of wall on 16 inch centers.

- Roofing - 1 lb. for every 60 sq. ft. of roof

- Siding - 1 lb. for every 40 sq. ft. of wall

Specialty nails are now available to handle almost any project.

- Steel are the general purpose nails used for most indoor framing and rough carpentry applications.

- Galvanized nails are plated with zinc which provides some corrosion resistance for outdoor applications.

- Stainless steel nails and screws are the best choice for outdoor applications.

- Copper nails are available for copper roofing and pressure treated lumber applications (copper nails do not have the strength of steel nails of the same length and diameter).

- Ringed nails provide a better grip than smooth shank nails and are very difficult to remove. Drywall nails are generally ringed as are many flooring nails

- Spiral or Ardox nails have a screw like thread and hold better than smooth shank nails but not as well as ringed nails. They are easier to remove than ringed nails but more difficult than smooth shank nails.