In many cases the difference between a professional pipe installation and a pipe installation done by a home handyman is that the professional’s pipe installation has the pipe running square and at right angles where the home handyman’s installation is crooked.

This article applies to all pipe, water and drainage, PVC, CPVC or copper.

The biggest problem that most home handymen face when installing pipe, is figuring out how to get the dimensions for sockets and fittings (Figure 1) correct.

Figure 1 - Copper pipe fittings

It is relatively easy to measure the distance between two objects. However, if that distance is where you want to place a piece of pipe you have to allow for the fittings and their sockets.

As an example:

We want to run a horizontal pipe inside a wall cavity. The horizontal pipe will connect to a vertical pipe at both ends, all as shown in Figure 1.

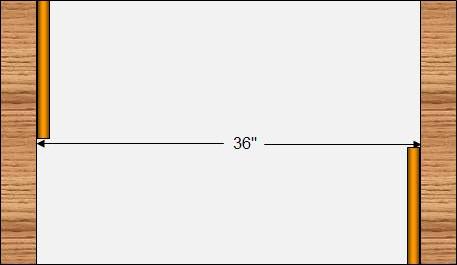

Figure 2 - Installing a copper pipe in a wall cavity

Measuring the inside dimension of the wall cavity, as shown in Figure 2, we find it is 36 inches long. We cannot cut a piece of pipe 36 inches long as we have two elbows involved, one at each end.

How to determine the installation allowance for pipe fittings:

Step 1

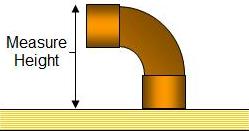

Place the fitting on a flat surface as shown in Figure 3.

Step 2

Measure the distance from the flat surface to the top of the fitting as shown in Figure 2. (Write the number down, because you won’t remember it!). In our example we will say that the fitting is 2 inches in height.

Figure 3 - Measuring height of pipe fitting

Step 3

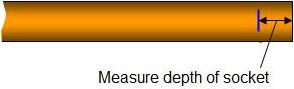

Insert a piece of pipe into the fitting. Make sure it is seated all the way in to the socket. In some cases it might be necessary to put some oil or grease on the pipe end to get it to fit all the way into the socket, as shown in Figure 4.

Step 4

Mark the spot on the pipe where the pipe meets the outside edge of the piping, as shown in Figure 4.

Figure 4 - Insert pipe in fitting & mark pipe

Step 5

Remove the pipe from the socket and measure the distance from the mark in Step 4 to the end of the pipe, as shown in Figure 4. In our example we will say that socket depth is 5/8 inch.

Figure 5 - Measure depth of pipe fitting socket

Using the information that we obtained in Steps 1 through 5 we can now determine the length of the piece of pipe that we need to connect the two pipes in our wall cavity.

Total distance in wall cavity 36 inches.

Fitting width or height is 2 inches

Socket depth is 5/8 inch.

The length of pipe we would need is 36 inches less the width of the two elbows which is 4 inches plus the socket depth for two fittings which is 1 1/4 inches. This equals 36-4+1 1/4 = 33 1/4 inches.