Problem: Metal and vinyl siding deformation and displacement.

Deformed or displaced siding can result in openings through which water will penetrate.

Cause: Poor detailing to accommodate thermal expansion and contraction.

Solutions:

- Make sure that the method of application does not restrict thermal movement. Expansion and contraction induced by changes in temperature cause the most problems with vinyl and metal siding. To accommodate this movement, follow these practices.

- Apply the siding according to the manufacturer's instructions.

- Use the nail slots provided in the siding, and make sure that nails are set in the center of the slots as shown in Figure 42. Do not nail through the material.

Figure 42 - Nail in center of slot with vinyl and metal siding

- Note 1: Nail in center of slot to allow for thermal expansion.

- Nailing should not be less than 16 to 18 inches (400 to 450 mm) o.c.

- Do not over-tighten nails as this may restrict movement as well as cause wavy siding. Allow approximately 1/32 inch (0.7 mm) between the nail head and the siding as shown in Figures 43a and 43b. Siding is "hung" not nailed tightly.

Figure 43a - Proper Nailing Of Vinyl and Metal Siding

Figure 43b - Improper Nailing Of Vinyl and Metal Siding

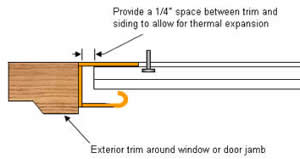

- Where siding butts into a window or door frame, provide a space, as recommended by the manufacturer. Most products use "J" trim to cover this space as shown in Figure 44.

Figure 44 - Exterior Trim Around Window And Door Jambs

- To make joints less noticeable, lap them away from streets and entrances.

- For vinyl siding, provide a suitable joint between individual pieces - some vinyl siding products use lap joints, whereas others provide accessories. Follow the manufacturer's installation instructions.