Problem: Noise Problems - Floor Squeaks - 1

Cause:

Lumber shrinkage.

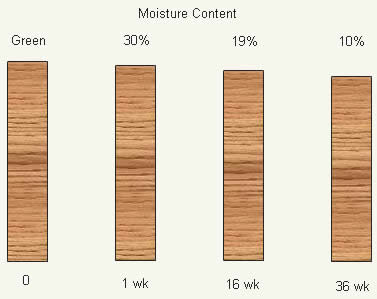

As dimensional lumber dries, it shrinks.

Many individuals are very surprised by how much shrinkage actually occurs, see Figure 1.

When shrinkage occurs, the fasteners loosen and effectively lose their grip on the sub-floor. As the sub-floor flexes under loads, it rubs against the fasteners, floor joists or against other sub-floor panels and material, producing squeaks and/or creaks.

Figure 1 - Shrinkage Versus Moisture Content For Kiln-Dried Lumber

It should be noted that many of the solutions offered to fix the problems such as using manufactured or engineered floor joists or beams is not a retrofit solution to noise problems caused by dimensional lumber shrinkage. It is impossible to replace floor joists once rough-in construction is completed

Solutions:

Use manufactured or engineered floor joists or beams:

- Manufactured or engineered floor joists and beams are constructed of dry, dimensionally stable materials. The flanges are constructed from dimensional lumber, and the webs are made form dimensional lumber, wood panels, or metal, see Figure 2.

Manufactured or engineered floor joists and beams remain dimensionally stable as moisture content remains relatively constant. The dimensional stability of manufactured or engineered joists and beams is one of the greatest benefits derived from using them.

Figure 2 - Two Styles Of Manufactured Or Engineered Structural Members (Floor Joists)

- While the manufactured or engineered floor joists and beams themselves do not shrink, you must take proper steps to ensure that where they connect to other materials those materials and the fasteners used are proper and adequate for the situation.

- Properly fasten the sub-floor to structural members. This will reduce squeaks and creaks and improve the overall performance of the flooring system.

Use dry lumber and allow time for shrinkage.

Using dry lumber, and allowing time for shrinkage to take place will reduce or even eliminate the amount of shrinkage that will occur.

Many building codes require that the moisture contend of lumber be not more than 19% when it is installed. S-DRY lumber must be at 19% moisture content or less when it is manufactured. You will minimize the amount of shrinkage by specifying this material and protecting it from the elements once it arrives at the building site.

- Using kiln-dried lumber will not necessarily eliminate shrinkage. Kiln-dried lumber can continue to shrink after leaving the kiln until the cells reach atmospheric moisture content (approximately 8% at 50% relative humidity (RH)). Even though kiln-dried lumber continues to shrink and can cause minor problems after the wood is installed in the building, these problems will be less severe than if green lumber (S-GRN) is used.

- Once installed, wood can dry to an even lower moisture content. Within the first year, wood usually dries to about 10% moisture content. By allowing the floor joists to dry for as long as possible in the house before you perform the final fastening, you can reduce the amount of squeaking that occurs. You must check fasteners and, where necessary, install additional fasteners before you install the final flooring.