Figure 1 - Damaged support column and foundation walls

Jacking-up a floor is hard work and a tedious job, that is not done in a day. It is definitely a project where you may want to consider hiring a professional. However, if you have a strong back and the knowledge it will save you substantially if you undertake the project yourself.

Causes of a sagging floors (Figure 1):

- Sill plates that are damaged or rotting.

- Foundation that is crumbling.

- Floor joists that are damaged, split or warped.

- Support columns that are damaged.

Sill Plates:

Figure 2 - Damaged sill plate

The sill plate is the piece of lumber that sits on the top of the foundation and provides a connection and resting point for the floor joists, as shown in Figure 2.

In order to replace the sill plate it is necessary to lift the floor joists off of the sill plate.

This is accomplished by jacking up the floor joists enough to have working space to make the repairs.

You cannot lift the floor of a home in one location, it is necessary to spread the weight of the floor. If you attempt to lift just one floor joist you will most likely push it through the floor above. To distribute the weight use a steel beam or 8 x 8 inch piece of lumber. The load on the jacks must also be distributed across a larger section of floor than the base of the jack provides. This can be accomplished with the use of a steel plate, minimum 3/4 inch thick or the use of two 8 x 8 inch beams.

The hydraulic jacks should, for a single story home should have a minimum weight rating of 10 tons and for a 2 story home a minimum weight rating of 20 tons.

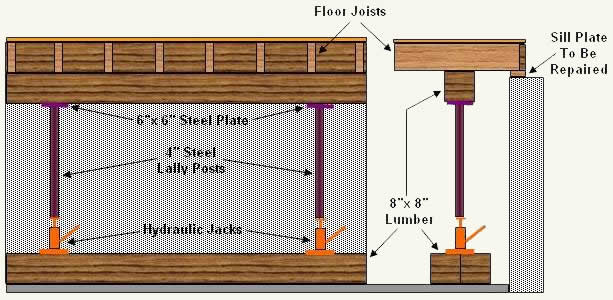

Figure 3 shows the jacking process:

Figure 3 - Jacking up floor joists

Raise each jack by 1/8 inch at a time, this will help to reduce any damage to window frames and plaster or drywall walls above the floor.

The 4 inch Lally posts can be replaced by 6 x 6 inch lumber. Make sure that the lumber or Lally posts are perpendicular when jacking or they may slip out of position. The 6 inch square steel plates help to distribute the load from the Lally posts.

The Lally posts, 6 x 6 inch lumber and hydraulic jacks can also be replaced or supplemented by the use of steel adjustable jack posts, as shown in Figure 4. These jack posts are harder to use to raise floors and have more value as permanent support posts, Figure 5) for a floor that needs additional support. The steel jack posts can be left in place as permanent support.

Figure 4 - Adjustable Jack Post

Figure 5 - Permanent Jack Post

Foundation Wall Replacement:

The same technique that is used to repair or replace a sill plate is used to replace or repair a foundation wall. A contractor may actually jack-up the entire home and replace all the foundation walls at once. Replacing all walls at the same time is not a home handyman recommended method. If all of the foundation walls need replacing and you are undertaking the project yourself, do one wall at a time.