A sagging roof, as shown in Figure 1a, is usually the result of a damaged or broken roof rafter. However, if it is a small area, it can be caused by damaged roof decking and in some rare cases a sagging roof can even be traced to an underlying foundation problem, as it is the house foundation that eventually takes the full load of the roof.

Figure 1a - Sagging Roof

Before a sagging roof can be repaired, you must first identify the cause of the problem.

The cause of the problem will not be visible from the top side of the roof, leaving an inspection of the underside of the roof as the only way to determine the cause of the sag.

Enter the attic, and inspect the rafters and the decking, take special note of the rafters and decking below the sag that is visible from the outside.

Note: Many people believe that a roof truss system can not be damaged, this is false. Roof truss systems fail at least as often as a on-site formed roofing system.

Things to look for:

- broken or cracked rafters as shown in Figure 1 and 2,

- broken or twisted metal or plywood gusset plates - used where the lumber members meet on a truss as shown in Figure 3.

- damaged, rotten, roof decking.

Figure 1 - Damaged roof rafter

Figure 2 - Split roof rafter

Figure 3 - Damaged truss gusset plate

While the best method of repairing any damage to a roof truss, rafter or decking is to work from the top of the roof, by removing the weather sheathing, underlayment, and then the roof decking itself, this is not always possible or practical due to the time of year and / or budget constraints.

Damaged Roof Truss Or Rafter:

The most difficult part of the project to repair a split or damaged truss member or rafter, is bringing the rafter or broken truss member back into its original position. This can be extremely difficult based solely on the logistics of getting into the area where the repair must be accomplished.

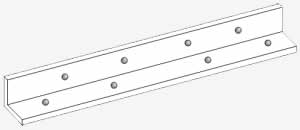

Figure 4 - steel "L" channel

The easiest way to bring a rafter or truss member back into shape is to use a piece of steel "L" channel, at minimum 1 1/2 inch X 1 1/2 inch and at least 2 feet long.

Drill 4 - 3/8 inch holes in the base of the steel angle stock and 4 holes in the side as shown in Figure 4.

Remove any broken splinters of wood that may prevent the rafter or truss member from re-aligning itself. This can be accomplished with a chisel or reciprocating saw.

Using 3/8 inch X 2 inch lag bolts on the bottom of the steel "L" channel, mount the steel "L" channel stock to the truss member or rafter end that is the most difficult to access. Drill through the holes in the side of the steel "L" channel and insert 3/8 inch X 2 1/2 inch carriage bolts and washers as shown in Figure 5.