Problem: Ceramic Flooring Tile Cracking - 1

Cause:

Inadequate base.

Cracking of ceramic tile floors usually occurs in the mortar joint between tiles, although the tiles themselves can also crack. Deflection of the supporting floor system or even vibration of the floor system can cause the cracking to occur. The mortar and the tiles themselves are very rigid an cannot accommodate much movement.

Solutions:

Block subfloor as required:

- Minimize the overall movement of the floor system and the deflections between structural members by reducing or eliminating differential movement between subfloor panels. This will help to reduce some of the cracking that can occur in ceramic tile floors.

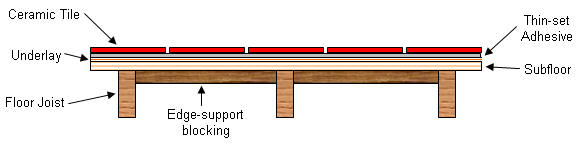

- It is recommended that you install blocking at all panel edges when using either tongue-and-groove subfloor panels or square-edged panels. This will provide a more solid base upon which to install the underlay as shown in Figure 30.

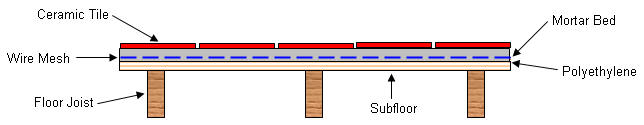

Figure 30 - Sub-Floor, Panel-Edge Blocking

Use recommended sub-floor materials and installation techniques.

- Follow the manufacturers' recommendations. Some manufacturers will not warranty their products if they are installed over oriented strand-board.

Use recommended underlay and recommended thickness.

- Your use of panel-type underlay will depend on whether you use a mortar bed. If the ceramic tiles are installed with adhesive, thin-set method, then underlay should be used as shown in Figure 31. If you use a mortar bed, underlay is not required, although it will help to stiffen the floor and reduce deflection.

Figure 31 - Thin-Set Method For Ceramic Tile Installation

- Most building codes do not specify the type of underlay material to use. The Terrazzo, Tile and Marble Association recommends using a plywood underlay when tiles are installed using adhesive or thin-set mortar. It does not recommend using strandboard, waferboard or particleboard.

- Building code requirements for underlay thickness for use with ceramic tiles applied with adhesive or thin set mortar are usually more restrictive than for other floor finishes.

A common code requires the use of 1/4″ (6 mm) underlay where the supports are spaced up to 12″ (300 mm) o.c. and 7/16″ (11 mm) underlay where the supports are spaced wider than 12″ (300 mm). As well, a common building code requirement is that fasteners be spaced not more than 6″ (150 mm) o.c. along the edges and not more than 8″ (200 mm) o.c. at other locations.

Use recommended mortar bed.

- Most building codes will recommend that ceramic tile be set in a mortar bed or be applied to a sound, smooth base with a suitable adhesive.

- The Terrazzo, Tile and Marble Association recommends polyethylene film be installed over the subfloor followed by a 2″ × 2″ ( 50 × 50 mm) galvanized wire mesh and a 1-1/4″ bed of mortar as shown in Figure 32.