The first set of tasks is to inspect the floor and the base cabinets that the concrete countertop will rest on.

- Make sure that the floor can support the weight of the concrete countertop. If your floors bounce or sag when you walk on them they will definitely have to be reinforced. If you are in doubt, contact a professional structural engineer to ensure the floors can support the additional weight of the concrete countertop.

- If the backs of the cabinets are made of Masonite or pressed paper they must be reinforced. Remove the fasteners which are holding the base cabinets to the wall and add a piece of 1/2 inch thick plywood to the back. The plywood should go from the floor to the top of the base cabinet so that it supports the weight of the countertop. Use construction adhesive to mount the plywood to the Masonite or pressed paper to the backs of the cabinets and apply screws through the plywood into the sides of the cabinets.

- If you have older style cabinets that are actually constructed on site with no backs or sides. Consider replacing the cabinets. These style cabinets provide little if any load transference for the countertop and if you place a countertop on this style of cabinet construction you will most likely find your countertop on the floor!

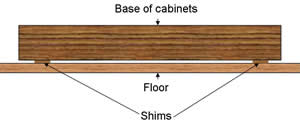

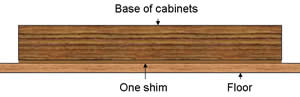

- The top of the countertop must be level in all directions. Ensure that the bottoms of the cabinets rest on the floor. In many cases cabinets will be shimmed in one or two spots to bring them to level. This is fine for standard weight countertops, but when using concrete you must shim the cabinet their entire length in order to distribute the weight of the countertop.

Figure 4, shows the bottom of a cabinet that is incorrectly shimmed for a concrete countertop. Figure 5 shows the bottom of a cabinet correctly shimmed for a concrete countertop.

Figure 4 - Incorrect method of shimming base cabinets

Figure 5 - Correct method of shimming base cabinets

Note: If you add support to the back of the base cabinets don’t forget to include this added depth to the measurements for your countertop. Your countertop will go from a width of 25 1/2 inches to 26 inches.

Tools

Many of the tools required are basic tools that are in most home handyman workshops. I would however like to point out that while many of the tools mentioned can be interchanged with others, the mold must be build precisely. It is difficult to create straight, no chip cuts on large sheets of laminate covered MDF without a table saw and a carbide tipped fine tooth blade, we highly recommend the use of a specialty blade such as an 80-tooth laminate blade (for example, a Freud LU98) or a precision cutoff blade (Freud LU85). These blades produce a smooth cut with a minimum of splintering or chipping along the cut edge. It is also difficult to cut true 90 degree angles without a miter saw or radial arm saw.

In order to round the inside edges of the mold for the hole for the sink you will need a router with a 3/4 inch roundover bit.

We suggest that the rebar and wire mesh be cut to size using bolt cutters to limit the generation of dust, however a grinder with a cutoff wheel or a circular saw with a metal cutting blade can be used.

We also recommend the use of a rebar bender, as shown in Figure 6, although a vice can be used to bend rebar, the accuracy of the bends is difficult even with a rebar bender. If you do not want to purchase a rebar bender you should be able to rent one from your local tool rental facility.

Figure 6 - Rebar bender

Probably one area where the home handyman fails when constructing a concrete countertop is in the provision of a strong and level workbench that is at least as big as the mold, both in length and width. It is almost impossible to build a concrete countertop without a proper workbench. We have some free workbench plans if you need to construct a stable and level workbench that will take the weight of the concrete countertop..

The second common mistake is to use tape measures that have loose or broken ends and straightedges that aren’t straight. It is extremely important that the tools you use to measure with are accurate. You will also need a carpenter’s or framing square, and a 4 foot level in order to check the level of the the base cabinets and workbench.

Of course you will need a cement mixer. Nine cubic foot cement mixers are usually the largest available and it is worth noting that you can only mix an amount of concrete equal to half of the capacity of the cement mixer. So if the rating of your cement mixer is 9 cubic feet you can only mix 4.5 cubic feet of concrete in it.

In order to grind and polish your concrete countertop you will require a variable speed concrete grinder. For the home handyman we recommend the Hardin variable speed concrete grinder and polisher, as shown in Figure 7. It is definately not a tradesman tool that would be used every day, but it is quite suitable for building a few countertops.

Figure 7 - Hardin variable speed concrete grinder and polisher

Note: You want to purchase or rent a variable speed concrete grinder, not a metal grinder. A concrete grinder should have an integral water line that is continually spraying water under the diamond grit grinding pad.

You will also need a number of diamond grit grinding and polishing pads and hand pads, as shown in Figure 8. In most cases you will need 50, 100, 200, 400, 800 and 1,500 diamond grit. The Hardin kit mentioned above, comes with a set of diamond grit grinding pads from 50 through to 3,000.

Figure 8 - Hand diamond grit polishing pads

In order to have the concrete flow around the reinforcement bars, wire mesh and into the corners of the mold, you should have a concrete vibrator. Most concrete vibrators used in construction for slabs and walls are too unruly and bulky for use when casting architectural concrete. The perfect solution is to use one of the smaller types of cordless concrete vibrators made by DeWALT or Makita, however, they are quite expensive. A very rational solution is a tool called a Vibe-all™, as shown in Figure 9. the tool obtains its power from almost any model of reciprocating saw.

Figure 9 - Vibe-all™ concrete vibrator

You will also need a variable speed electric drill a variety of hand tools and other items. These include a quantity of 5 gallon pails, bathroom scale, kitchen scale, vacuum cleaner, clean rags, calculator, note pad, pencil, inexpensive watch, wood and magnesium float, screed, pool trowel, margin trowel, steel finishing float, hammer, small pry bar, screwdrivers, drill bits, countersink bit, clean wood shims, and a lot of patience, not to mention an appropriate amount of brawn.

Continued - How to make a concrete countertop template

How to Make Concrete Countertops - Index