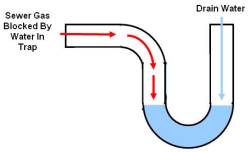

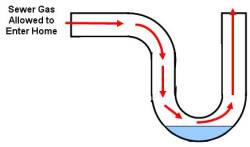

The drain traps installed on all drainage lines going to all plumbing fixtures with the exception of the toilet are critical for the health and comfort of your family. The trap traps

water which in turn prevents sewer gases from entering the living quarters of your home, as shown in Figures 4 and 5.

Figure 4 - Filled drain trap prevents sewer gas from entering the home.

Figure 5 - Empty drain trap allows sewer gas to enter the home.

The toilet has its own water trap molded into the porcelain bowl section.

Note: If you have sinks, toilets, showers and/or bathtubs that are not used often, water should be placed down the drain (toilets flushed) every 30 days. The water in traps will evaporate over time, by pouring water down the drain or flushing the toilet you replace any water that may have evaporated preventing sewer gas from entering the home.

Water Supply:

The water supply lines are relatively easy to install compared to the drainage and vent piping. Because they can be installed in any direction, with bends and loops they can easily avoid any obstacles such as the drainage lines. There are a few items to consider during the installation of the hot and cold water lines.

Many older homes used galvanized piping for the water supply. Over time, galvanized water pipes corrode and develop leaks, as shown in Figure 6.

Figure 6 - Corroded galvanized water pipes.

Galvanized pipes were replaced by copper. Copper piping will last forever.

Now many homes have the internal water piped in plastic and PEX pipes (check your building codes, in some areas plastic cannot be used in others plastic can only be used for cold water).

Figure 8 - Water shut-off valves

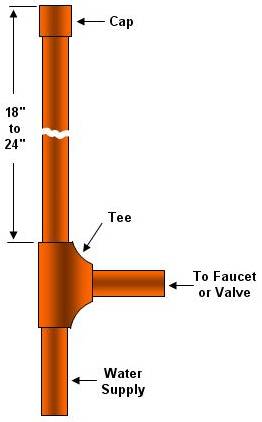

Figure 7 - Water piping using a Tee to stop water hammering

While plastic has the advantage that it is easy to install, I prefer to stick with copper piping as I have more confidence in the connections and in the copper pipes ability to deflect most nails.

Install, water shut off valves, as shown in Figure 8, in convenient access areas for all hot and cold water lines just before the connection to the faucets or toilet tank. The shut-off valves come in a variety of configurations and pipe connections. By having individual shut-off valves making repairs, replacing washers and faucets and replacing toilet tank valves becomes a relatively easy project.

Note: As a preventive maintenance measure it is wise to turn your valves off and on once a year. Valves are not used often, but when needed in order to accomplish a repair they are invaluable. Valves that are not used will end up with heavy concentrations of calcium on the inner valve stems, making them difficult to close. By turning them off and on once a year you will ensure that they are available to work when you need them.

Although not a necessity, I recommend that all water pipes be covered with a foam insulation, as shown in Figure 9. The foam insulation keeps the hot water from dissipating its heat through the copper piping, hence saving you energy. Foam insulation also reduces the noise generated when the water is travelling through the pipes. The insulation is relatively inexpensive and it is not something that can be easily added at a later date.